Puspo Utomo and Sunardi Tjandra

Engineering Management Laboratory

Industrial Engineering Department – University of Surabaya

E-mail: puspo@ubaya.ac.id

Abstract

PT. X is a company that produced and assembled sandals/shoes components. The factory has recruited non permanent workers for the labeling process in the packaging department that consisted of stapling and punching activities. Working position and method caused the operators worked uncomfortably in the cross-leg position on the floor without any adequate supporting facilities and the standard time was 11.04 s.

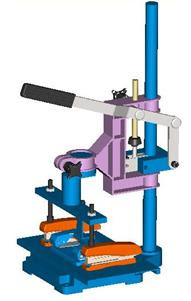

With the help of Pro-Engineer Software, a fixture using spring and lever mechanism that combine stapling and punching processes was designed and simulated. The minimum force needed to operate this fixture well was approximately 10 N.

Implementing this fixture combined with using a set of table and chair, some improvements on the working condition, method and time reduction have been achieved. Operator complaints and pain were reduced, process time was reduced to 6.75 s., and numbers of labors were reduced too.

Although this fixture has improved the production process, a specific weakness on the reload of the stapler content took the longer time then the initial ones.

No comments:

Post a Comment